FEATURES

What is steam exactly?

Steam is water which has been changed into a gas. Steam cannot be seen for it is colorless. The cloud of vapor that we see beginning about 2 centimeter from the spout of a teakettle is not steam. The real steam is in the space that seems vacant just outside the spout. The cloud we see is the water that the cooler air has changed from a gas form back into tiny water particles.

Steam is formed by boiling or by evaporation. At sea level water boils when it is heated to 100° C. Water also evaporates at lower temperatures. The steam caused by boiling is as hot as the boiling water. The steam caused by evaporation is not hot. Usually, the word steam refers to hot steam. When water reaches the boiling point, bubbles of the steam begin to rise through it and escape into the air. The temperature will remain at the boiling point until all the liquid has become gas. It requires 100 calories of heat to raise one gram of water from the freezing point (0°C) to the boiling point.

Steam fills more space than the water from which it comes, at the moment when boiling stops, the gas is 1,67 times as great in volume as the former liquid. At this stage it is called saturated steam, if heated more, it takes up even more space. Then it is known as super heated steam. The steam engine is built on this principle.

Our technology

Standard Boiler

In the basic version of steam generators, the boiler works also as a reservoir for fresh water. With a load of water you can work about 2 hours (depending on the model). The boiler is always made of anti corrosive and anti-scale 304 stainless steel in order to guarantee duration in time of the steam generator.

Unlimited Autonomy

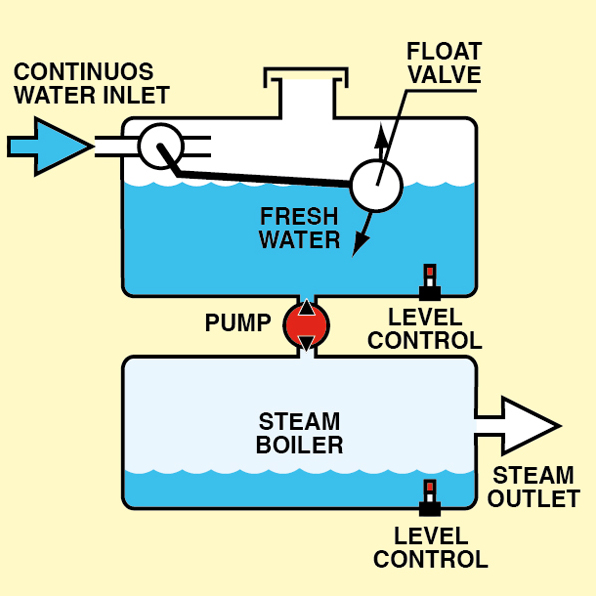

Steam cleaners with this feature have two water chambers: a pressurized boiler tank and a non-pressurized tank. That allows the operator to add water to the machine while it’s still running. Menikini’s unlimited autonomy steam cleaners are equipped with an electronic level sensor that refills the boiler when the level of water inside it is not enough. As a result, the machines avoid drops in pressure and temperature during use.

Continuous fresh water inlet

Some of our industrial steam cleaners include an automatic direct water refill that connects the machine to a water pipe and refills the fresh water tank as needed. Continuous water refill systems can also be refilled manually if a water line is not available.

Detergent tanks

These tanks hold and dispense cleaning chemicals. Some of our steam cleaning machines include simple handle controls that allow the operator to control the detergent and steam flow while cleaning.

BENEFITS

Ecological

- conserve water while reducing waste and pollution

- maintain an environmentally neutral workplace

- reduce chemical disposal

- prevent ground water contamination

- aid in maintaining cleanliness

- minimize chemical packaging

- reduce amount of waste products in landfills

- lower carbon footprint of chemical cleaner production

Sustainability means taking the long-term view of how our actions affect future generations and making sure we don’t cause pollution or deplete resources at rates faster than the earth is able to renew them.

Saturated dry steam is a completely green technology that makes sanitizing possible in an environmentally friendly way without the use of harsh chemicals.

Menikini super heated, saturated dry steam vapor products contribute towards sustainability while saving money on water, chemicals, labor and costly production downtime.

The dry steam contribution

The use of saturated dry steam dramatically reduces water consumption in all domestic and industrial cleaning activities. Menikini technology gets excellent cleaning and sanitizing results saving up to 100 times in washing water, significantly contributing to its conservation.

Chemical free

The pollution and the contamination of the ground and water are a global problem. It is our duty, not just from a moral point of view, to find a solution by investing in applications that drastically reduce the consumption of water and the use of pollutant detergents. Saturated dry steam guarantees an optimal cleaning and sanitizing. It is also an ecological method of deep cleaning as it removes chemical, toxins and dirt without using solvents.

Latent heat transmitted by saturated dry steam from Menikini eliminates all types of pathogenic micro-organisms and harmful bacteria, but does not result in bacterial resistance, as is often the case with chemical disinfectants.

- no ground contamination from unnecessary solvents

- save time by cleaning without swilling and rinsing

- avoid allergies and skin irritation

- protect the taste of food and wine

Economical

- cut labor costs (30% less manpower)

- reduce water consumption (80% less water)

- cost savings on waste water purification.

- reduce disposal costs (90% less detergent)

- reduce system and line down time

- reduce toxic waste

- improve quality inspection

- use only pure water energy

- easy and safe to use

- no need to touch dirty areas or chemicals

- reach into angles and small cracks

- sanitize as well as clean

- can be used on electrical parts

The result is a more efficient and profitable cleaning operation.

Social

- improve health, safety and overall appearance of facility

- reduce exposure to chemicals

- prevent handling of potentially harmful substances by employees

- eliminate unpleasant odors

- improve indoor air quality

- reduce dirt and dust particles in the air

- reduce risk of accidents

- ensure clean, dry and safe walkways

- minimize workplace noise for anytime cleaning

The result is improved worker and customer safety, enhanced quality of work life and increased occupant satisfaction.

HEALTH

Kill Germs & Bacteria

With prolonged periodic use, over time, bacteria and viruses become resistant to treatment by chemical products.

This can have grave repercussions in environments where hygiene is an absolute imperative, as in the food and medical industries. Over time, it is necessary to increase the amount of detergents and disinfectants used to maintain the required hygienic results.

This increases the risk of chemical contamination of food products. In addition, as many people are allergic to detergents, their usage can have serious effects in hospital environments.

Pathogenic agents are not resistant to the thermal shock of vapor cleaning. Research has demonstrated that Menikini saturated steam treatment eliminates 99% of bacterial fungi and mold on virtually any surface. Unlike other cleaning methods, vapor is able to enter into all surface cracks and crevasses. Even with frequent vapor cleaning, pathogenic agents are unable to build up immunity to the thermal shock.

The absence of water, the instantaneous drying of the cleaned surfaces and the reduced use of detergents are all factors which help maintain the optimum sanitary conditions.

Fight Allergies & Diseases

Allergens produced by house dust mites are among the most common triggers of asthma. There are at least 15 mite allergens.

Studies have shown that a significant portion of adult asthma is due to atopic sensitization to dust mites. It has been estimated that as many as 1.2 billion people could have some form of chronic sensitization to dust mites.

Typical symptoms of house dust mite allergies are itchiness, sneezing, inflamed or infected eczema, watering/reddening eyes, runny nose and clogging in the lungs.

The environment of bedding is optimal for most dust mites, and comparative studies have shown that the density of dust mites in mattresses to be on average greater than 2500 per gram of dust.

Cleaning beds with most vacuum cleaners will not remove dust mite allergens, but instead throw them into the air and increase their volatility.

Exposure to a high temperature shock will typically prove fatal to house dust mites. Cleaning with dry steam at lethal temperatures has been shown to be sufficient to kill all the dust mites in bedding.

Protect your loved ones from parasites

- Ticks

These small arachnids are living on the blood of mammals and birds. They are vectors of a number of grave diseases. They are often brought into the home by pets. There are often alarming stories of ticks infesting trains and other public transport. Vapor cleaning is the best weapon against these infestations. Vapor also penetrates into cracks and crevasses where ticks can hide. - Bedbugs

An old pest re-emerging with a vengeance. The presence of bedbugs throughout the world has taken the human population like a Tsunami. Pest management specialists have had to play catch up on how to successfully combat these persistent blood sucking insects. We have now learned that bed bug management cannot be accomplished using pesticides alone. A systematic approach is needed. Until recently, professionals were recommending throwing away affected box springs and mattresses. Fortunately, today we have discovered that dry steam when applied to the mattresses, couches and carpets will virtually eliminate all stages of the bedbugs including the hard to kill eggs. Vacuuming helps, but it will not remove all of the bedbug eggs that are stuck to the mattress and other surface. Even vigorous vacuuming will not remove all of the eggs. - Mites and acari

Mites cause several forms of allergic diseases, including hay fever, asthma and eczema and are known to aggravate atopic dermatitis. Mites are usually found in warm and humid locations, including beds. It is thought that inhalation of mites during sleep exposes the human body to some antigens that induce hypersensitivity reaction.

Dust mite allergens are thought to be among the heaviest dust allergens. Treatment of mite allergy starts with avoidance. Regular steam sanitizing of mattresses and blankets can help in this regard. - Fleas This small wingless jumping insect feeds on the blood of mammals and birds. It sometimes transmits diseases through its bite. Com-batting a flea infestation in the home takes patience because for every flea found on an animal, there could be many more developing in the home.

The environment should be treated with a spray insecticide. Frequent vacuuming is very helpful, but the vacuum bag must be disposed of immediately afterwards. The combination of dry steam and vacuuming should eliminate fleas definitely from the environment. - Improve indoor air quality

HACCP

Fight risks of food safety hazards

Hazard analysis and critical control points, or HACCP, is a systematic preventive approach to food safety and pharmaceutical safety that addresses physical, chemical, and biological hazards as a means of prevention rather than finished product inspection. It involves monitoring, verifying and validating of the daily work that is compliant with regulatory requirements in all stages all the time. HACCP is used in the food industry to identify potential food safety hazards, so that key actions can be taken to reduce or eliminate the risk of the hazards being realized. The system is used at all stages of food production and preparation processes including packaging, distribution, etc.

The Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) say that their mandatory HACCP programs for juice and meat are an effective approach to food safety and protecting public health. The use of HACCP is currently voluntary in other food industries. Hence, HACCP has been increasingly applied to other industries, such as cosmetics and pharmaceuticals. This method, which in effect seeks to plan out unsafe practices, differs from traditional “produce and test” quality control methods which are less successful and inappropriate for highly perishable foods.

HACCP application range

- Fish and fishery products

- Fresh-cut produce

- Juice and nectar products

- Food outlets

- Meat and poultry products

- School food and services

The development, implementation, and certification of an HACCP system, besides enhancing the efficiency of the production plant resulting from the minimization of production rejects and returns, also enables the manufacturing companies to offer a completely guaranteed product quality to their customers.MORE

The Menikini machines, put to the test to evaluate the effectiveness of steam in damping fungi and bacteria, have been proved to be more and more effective, amply within the parameters specified by the European standards related to chemical and antiseptic disinfectants.

For all cleansing and sanitizing activities hereunder reported, traditional systems may be replaced with the use of saturated dry steam with advantages regarding water, detergent and disinfectant consumption. Usually where meals are prepared and administrated the following equipment is present:

- refrigerators and cold stores

- rapid temperature decrease

- thermal convection ovens

- microwave ovens

- deep-fryers

- braziers

- water-boilers

- pasta-cooker

- dish-washers

- slicing-machines

- mincing-machines

- citrus-fruit squeezers

- mixers

- emulsifiers

- drinks distributors

- ice-cream dispensers

- ranges and heating plates

Handbook for a correct sanitary routine

Part of the handbook for a correct sanitary routine with reference to restaurants, edited by “Federazione Italiana pubblici esercizi” (Italian Federation of Public businesses), will be hereunder reported. Ministry of Public Health judged it in compliance with the article 3 of the decree law 1997, n° 155. The handbook which we refer to has been edited in order to give the information, the instruments, the methods to apply the HACCP to the preparation and administration area of meals with reference to restaurants. To such area belong the following:

- Restaurants: Restaurants, Inns, Fast food, Self Services, Pizzeria, Snack-bars, Private Clubs, etc…

- Restaurants/Hotels: Hotels, Boarding-houses, Tourist Villages, Youth-Hostels, Vacation houses, etc…

- Collective restaurants: canteens, cafeteria, refectories of firms, schools and hospitals, etc…

- Premises for old people: Nursing homes.

The following paragraphs, quoted hereunder from the handbook, may serve as useful indications for the cleaning and sanitizing procedures to be undertaken. The sequence of the cleaning operations should be carried out as reported hereunder:

Removal of coarse residuals

Cleansing

Sanitizing

The removal of coarse residuals is the first operation to be carried out during the cleaning operations. It should be carried out every time a process ends and it consists of removing from the work areas all the residuals which were originated during the raw material processing and which would hinder further cleaning operations. Traces of flour, sugar, powders, packaging parts, liquid and other materials should be removed by means of sweeping of the floors and dusting of tables and equipment.

Cleansing is the operation which enables the removal of dirt from the surfaces so as to make them become visibly clean. Dirt may be classified as normal dirt or fat dirt. In order to remove such dirt detergents are used …. pay attention to the technical safety data, all detergents have toxicity characteristics.

Sanitizing is a process which aims at destroying the pathogenic germs and the other micro-organisms. The chemical agents which are mostly used by the firms where food is dealt with are: Chlorine-based components, Quaternary ammonium salts…. It is important that sanitizing is carried out only after an accurate cleansing, even a great use of disinfectant is not effective if grease residuals and dirt remains on the treated surface…. The duration of the contact between disinfectant and surface is very important, usually 10-15 minutes are required …. Surfaces treated with disinfectant must be abundantly rinsed afterwards in order to avoid contamination with food…. In the document it is also quoted the saturated dry steam technology with the following words: “pressured Dry Steam with temperatures between 140°-185° C represents the most ecological and modern method to attack dirty surfaces. Pressure, associated with heat action, plays an efficient cleansing and disinfecting action on all kind of surfaces…. Pay attention to the machinery characteristics, they should be provided with manometer and thermometer” in order to be able to check the pressure the boiler is operating at and thereafter the temperature of the generated steam. Saturated steam enables therefore to operate both in the cleansing and in the sanitizing phase.